Makhe sibone ukuba isebenza njani:

Wumnqwazi nguCinezela-ngena?

I-Press-fit lungenelelo olulingana phakathi kwamalungu amabini apho inxalenye enye inyanzeliswa phantsi koxinzelelo kumngxuma omncinci kwenye.

Ngokoqobo, luhlobo oluthile longenelelo olufanelekileyo.

Itekhnoloji yokucofa ifanelekile isetyenziswa kakhulu, kwaye uqhagamshelo kwiPCB sesinye sezicelo zayo eziqhelekileyo.

Xa sichaza ngesiTshayina, sihlala sisebenzisa amagama ahlukeneyo afana ne-crimping, i-press fittting, kunye ne-crimping.Ishishini lihlala lisetyenziselwa ukusebenzisa ngokuthe ngqo "Cofa kufanelekile" ukuchaza.Olona gxininiso lweli nqaku lukwayisicelo esifanelekileyo soshicilelo kushishino lwePCB (izikhonkwane ezininzi zoshicilelo olufanelekileyo).

Zeziphi iingenelo zePress fit?

Ezona ndlela ziphambili zokufakela iinxalenye kwiPCB kukuwelda kwaye ucinezele kufanelekile.Makhe sithelekise izinto eziluncedo kunye nezingeloncedo kwezi ndlela zimbini zonxibelelwano kunye nedatha eqhelekileyo.

| Ukusoda | Cinezela-ngena | |

| ukusetyenziswa | 30-40 kW | 4-6 kW |

| okusingqongileyo | Welding umoya kunye nokuhlala | Akukho ndawo yokuhlala |

| iindleko | Ufuna iPA, PPS | Akukho ngxaki yobushushu obugciniweyo, sebenzisa izinto eziphantsi kwexabiso eliphantsi njengePBT, PET njl. |

| Izixhobo | Utyalo-mali olukhulu kunye neendleko zendawo enkulu | Utyalo-mali oluphantsi kunye nobukhulu bendawo encinci |

| Indawo ekhoyo | 5-15mm | 2mm |

| Izinga lesiphako | 0.05 kufanelekile | 0.005 kufanelekile |

Ukusuka kwidatha yokuthelekisa, sinokubona ukuba i-Press fit iyindlela engcono yokudibanisa i-PCB kune-welding ngokwezalathi ezithile zokusebenza.Ngokuqinisekileyo, ukuwelda akunamsebenzi, kungenjalo akuyi kubakho amanqaku amaninzi kwi-PCB.Umzekelo, i-welding ihlala inonyamezelo olukhulu lokunyamezelana kwedimensional yezikhonkwane, kwaye uqhagamshelo lwe-welding luzinzile, Nangona kunjalo, i-Press Fit ingcono kwiimpawu ezininzi zeempawu.

Iindlela zoyilo eziQhelekileyo zokucinezela

Ngaphambi kokwazisa indlela yoyilo, kuyimfuneko ukwazisa amagama amabini asetyenziswa ngokuqhelekileyo:

I-PTH: Ityatyelwe ngomngxuma

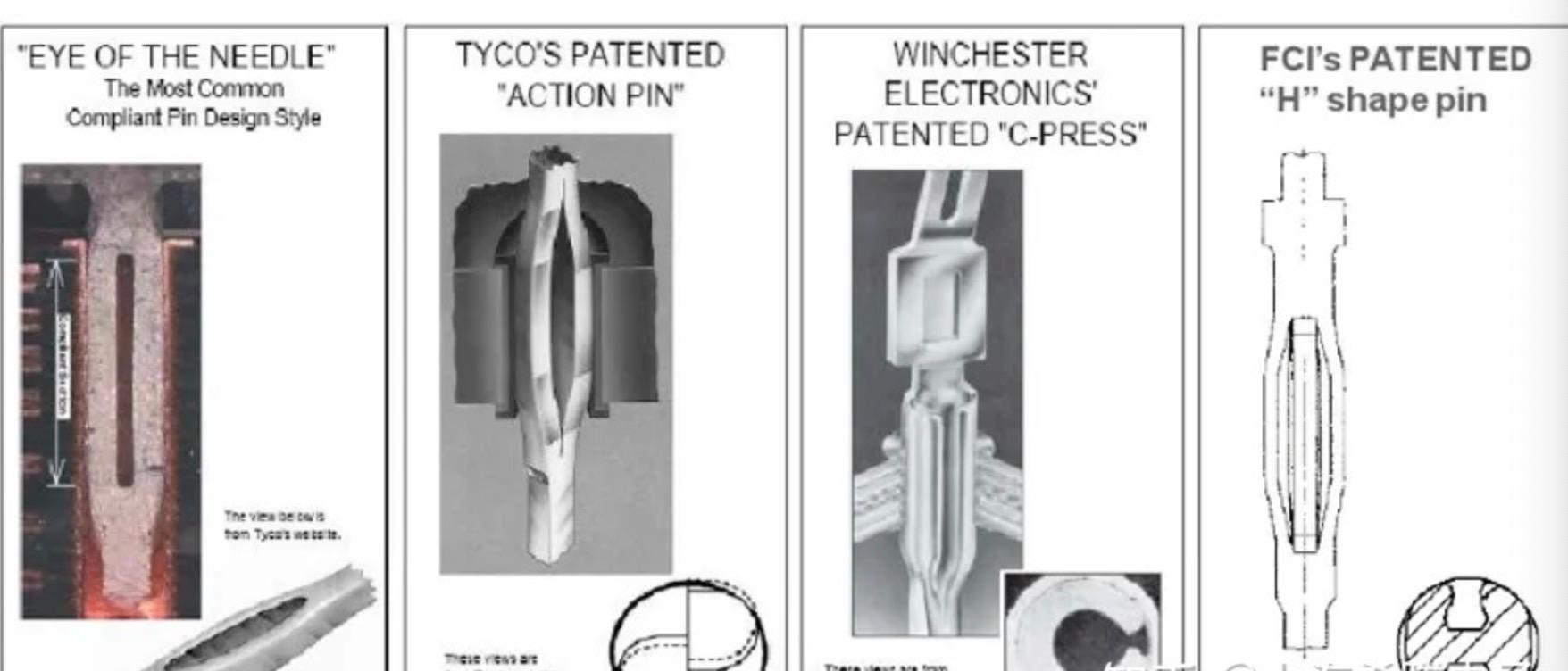

EON: Iliso leNaliti

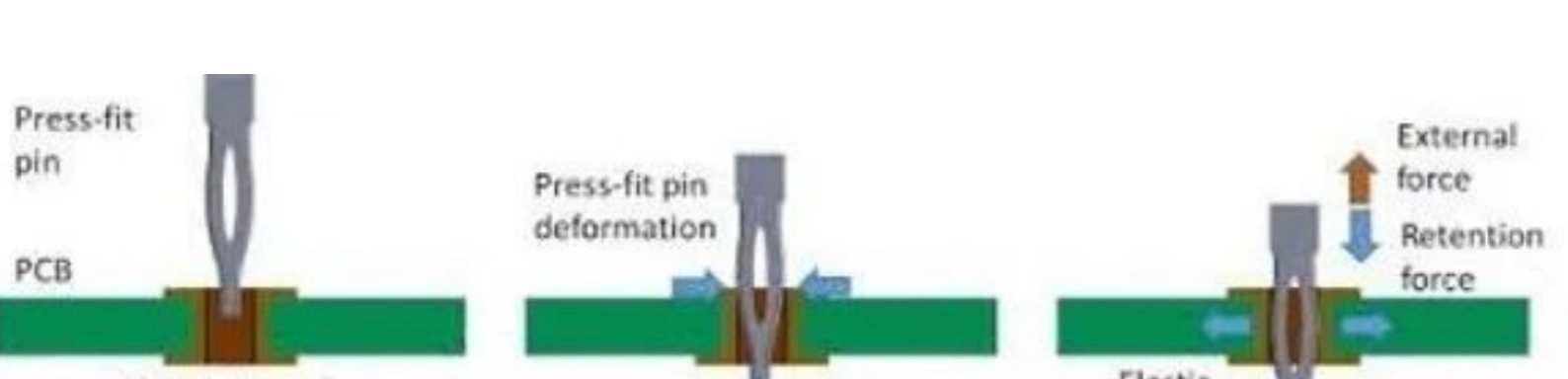

Okwangoku, izikhonkwane ezisetyenziswe kwi-Press fit ngokusisiseko zizikhonkwane ezilastiki, ezikwabizwa ngokuba zizikhonkwane ezithobelayo, ezidla ngokuba zikhulu ngobubanzi kunePTH.Ngethuba lenkqubo yokuhlanganisana, iinxalenye zenaliti ziya kuphazamiseka, okubangela ukudibanisa kwendawo kunye ne-PTH eqinile.Xa kuthelekiswa nenaliti eqinile, inaliti ehambelanayo inokuvumela ukunyamezela okukhulu kwe-PTH.

Inaliti yomngxuma wepin ngokuthe ngcembe ibe yeyona nto iphambili kwimarike.Ilula kuyilo kwaye ingasetyenziswa kunye namalungelo abenzi avulekileyo.Nangona ayifuni umzamo omkhulu woyilo, ingasetyenziselwa kunye nezisombululo zoyilo esele zenziwe, ezineempawu zamandla aphantsi okufakwa kunye nokugcinwa kwamandla aphezulu.

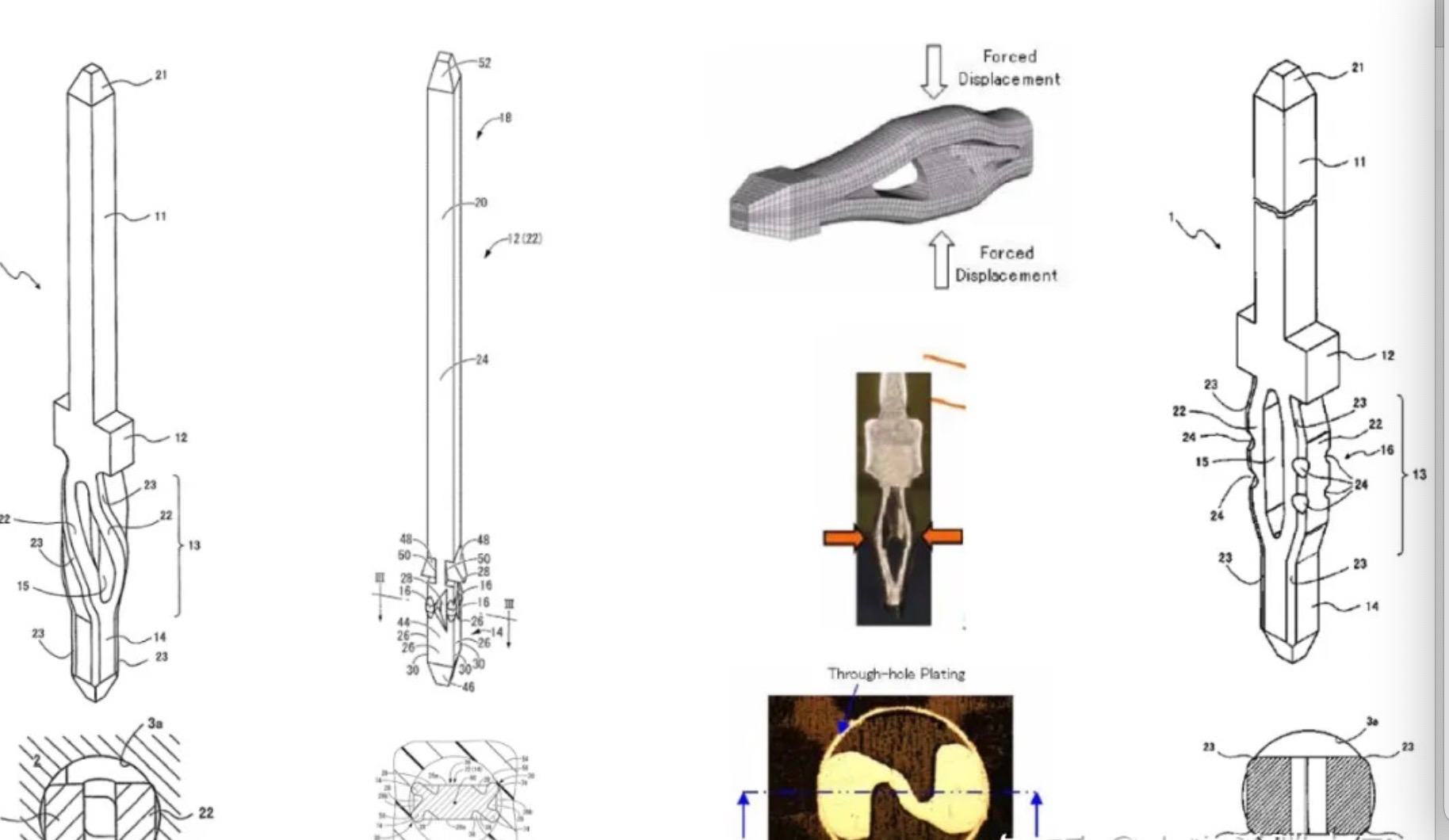

Lo mzobo ungasentla ubonisa iphini eliqhelekileyo/izakhiwo zesiphelo.Eyokuqala yinkqubo yoyilo eqhelekileyo.Iskimu sokuyila i-pinhole esisisiseko silula kwisakhiwo, kodwa sifuna i-symmetry ephezulu kunye nendawo;Eyesibini yimveliso yepatent ye TE Company.Ngokusekelwe kwisakhiwo se-pinhole, ine-angle encinci yokujikeleza, ekwazi ukuziqhelanisa nemingxuma eyahlukeneyo.Nangona kunjalo, ineemfuno eziphezulu zobukhulu bomngxuma, kwaye iya kuvelisa amandla athile okujikeleza emngxunyeni;Eyesithathu yi-patent yaseWinchester Electronics yangaphambili "C-PRESS", ebonakaliswa yi-C-shape evela kwicandelo lomnqamlezo.Iingenelo kukuba amandla oxinzelelo aqhubekayo, i-PTH deformation incinci, kwaye i-disadvantage kukuba i-PTH ene-aperture encinci inzima ukuyifumana;Eyokugqibela yi-H-type pin ye-FCI Company.Inzuzo kukuba kulula ukuyilawula xa i-crimping, kodwa i-disadvantage kukuba kunzima ukwenza i-pin yoqhagamshelwano.

Izinto eziqhelekileyo kunye nenkqubo yokuvelisa

Izinto eziqhelekileyo zePin ziquka i-tin bronze (CuSn4, CuSn6), ubhedu (CuZn), kunye nobhedu olumhlophe (CuNiSi), phakathi kwayo ubhedu olumhlophe lunomgangatho ophezulu we-conductivity, kunye nokushisa kokusetyenziswa kunokudlula i-150 ℃;Ukugquma ngokuqhelekileyo kugqitywe nge-electroplating okanye i-hot dip plating μ m + 1 μ M ye-Ni + Sn, i-SnAg okanye i-SnPb, njl. Njengoko kuchazwe ngasentla, isakhiwo sePin sihluke, kwaye injongo yokugqibela kukuvelisa iPin enezincinci ezincinci. amandla oxinzelelo kunye namandla amakhulu okubambisa phantsi kweemeko zokwenza lula kunye neendleko eziphantsi.

Izinto ezisetyenziswa ngokuqhelekileyo ze-PTH yi-glass fiber+epoxy resin+copper foil, enobukhulu>1.6, kwaye i-coating ngokubanzi yi-tin okanye i-OSP.Ubume be-PTH bulula.Ngokuqhelekileyo, inani le-PCB layers likhulu kune-4. I-aperture ye-PTH ingqongqo ngokubanzi, kwaye iimfuno ezithile zixhomekeke kuyilo lwePin.Ngokuqhelekileyo, ubukhulu be-copper plating bu malunga ne-30-55 μ m.Ubunzima bokubekwa kwetoti gabalala yi-1 μm.

Uhlalutyo lwenkqubo yokufakwa kweendaba/yokukhupha

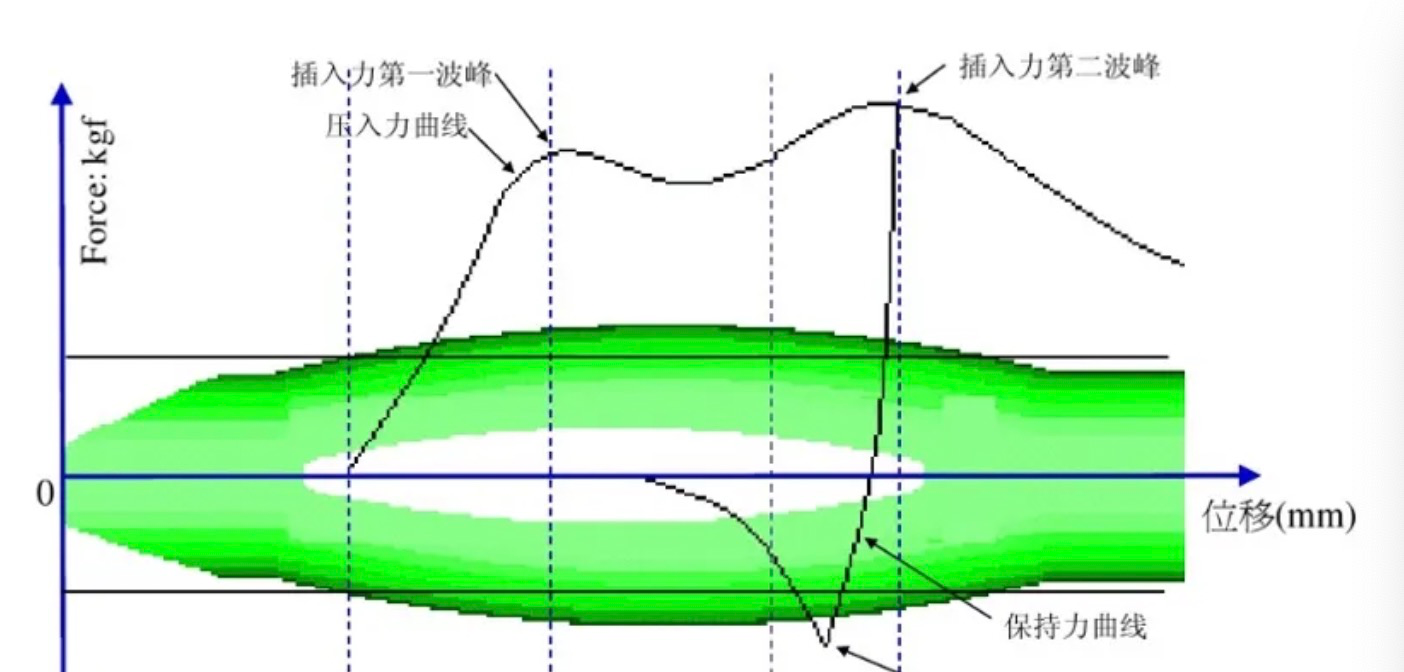

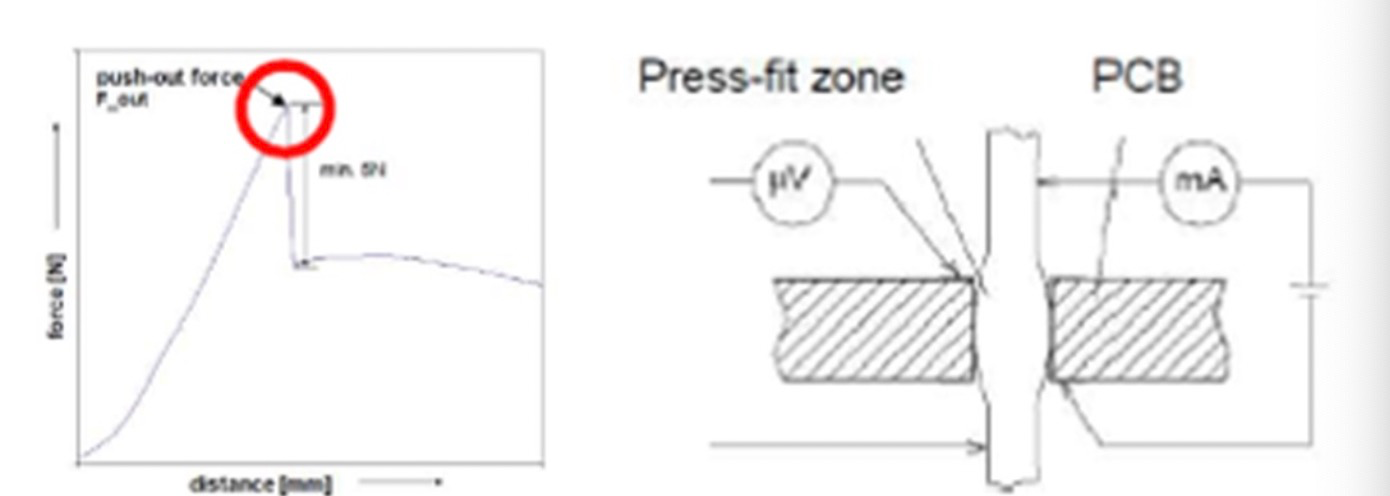

Ukuthatha i-pinhole yesakhiwo esiqhelekileyo njengomzekelo, njengoko kubonisiwe kumzobo ongezantsi, kukho utshintsho oluqhelekileyo lwe-curve yoxinzelelo kuyo yonke inkqubo yokucinezela kunye nokukhupha ngaphandle, okukwanxulumene noyilo lwesakhiwo sePin.

Cinezela kwinkqubo:

1. I-Pin ifakwe emngxunyeni, kwaye i-tip ingena ngaphandle kokuguqulwa

2. I-Pin iqala ukucofa ngaphakathi, i-EON iqala ukonakala, kwaye incopho yokuqala yamaza ibonakala kwinkqubo yocinezelo.

3. I-Pin iyaqhubeka nokucinezela, i-EON ngokusisiseko ayinayo enye i-deformation, kwaye i-pressure force iyancipha kancane

4. I-Pin iyaqhubeka nokucinezela phantsi, ibangela ukuguqulwa okungaphezulu, kunye nencopho yamaza esibini

Ivela kwinkqubo yokucinezela

Kwimizuzwana ye-100 emva kokuba ukufakwa kweendaba kugqityiwe, amandla okugcina aya kuhla ngokukhawuleza, kunye nokuhla malunga ne-20%.Kuya kubakho iiyantlukwano ezihambelanayo ngokwezoyilo ezahlukeneyo zephini;Iiyure ze-24 emva kokufakwa kwe-press, inkqubo ye-welding ebandayo ye-Pin kunye ne-PTH igqityiwe.

Oku kubangelwa iimpawu ezibonakalayo zetsimbi, kwaye kukho indawo encinci yokuphucula.Inokuqinisekiswa ukuba amandla okugcina okugqibela ayahlangabezana neemfuno zoyilo lwemveliso ngovavanyo lokutyhala ngaphandle.

2. Ezinye iindlela zokungaphumeleli ngexesha lokufakwa kwePin

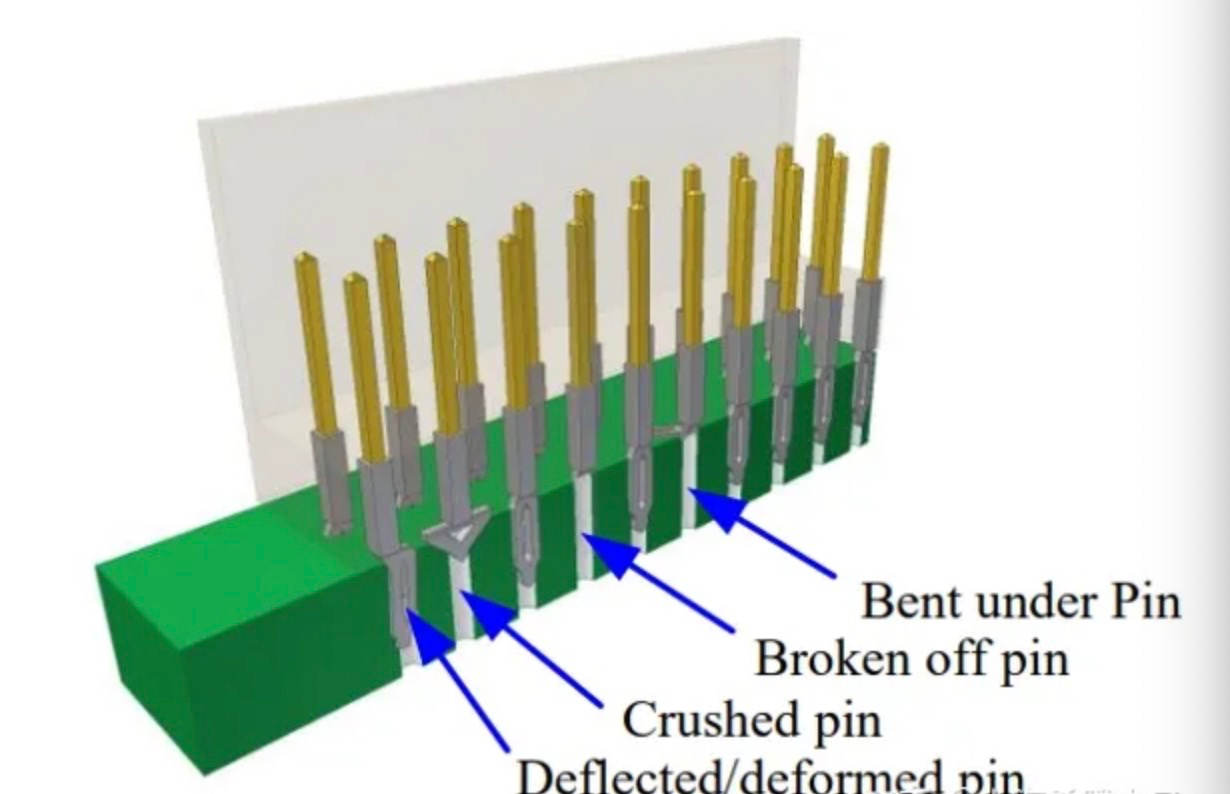

Njengoko kuboniswe kumzobo ongezantsi, ipini inokuthi ikhubazeke, ityunyuzwe, ityunyuzwe, iqhekezwe kwaye igobe ngexesha lokufakwa.

Ezi ziindlela zokungaphumeleli ezinokwenzeka zephini loqhagamshelwano ngexesha lenkqubo yokufaka i-press.Ekubeni i-pin yoqhagamshelwano kufuneka ifakwe kwi-PTH, kunokwenzeka ukuba ayinakubonwa ngokubonakalayo emva kokucinezela, kwaye umonakalo wamandla omatshini awunakufunyanwa ngovavanyo lokusebenza kombane.

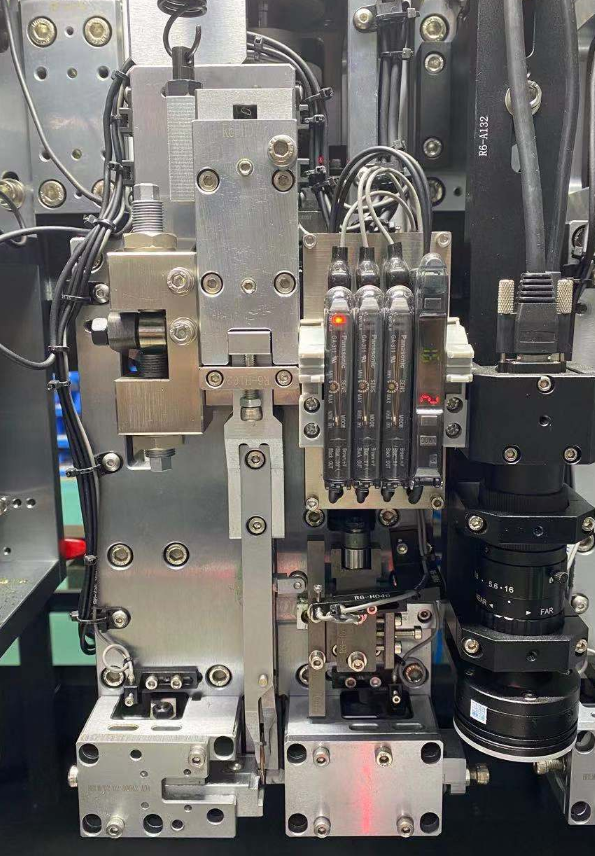

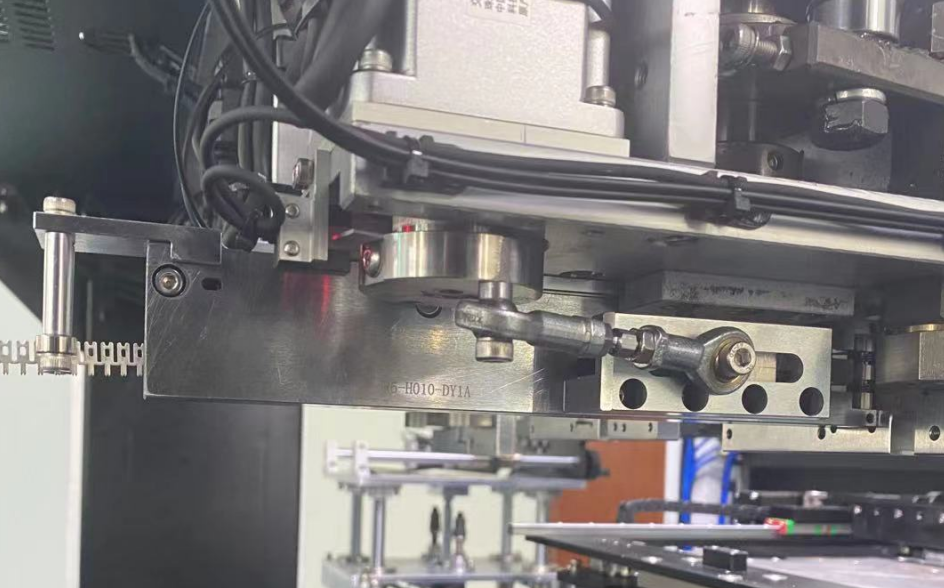

Ezi ndlela zokungaphumeleli kufuneka zibekwe esweni ngexesha lenkqubo yokufakwa kweendaba.I-PROMESS ibonelela nge-curve corridor, ifestile, ixabiso eliphezulu kunye nelona xabiso lincinci kunye nezinye iindlela zokubeka iliso ukuqinisekisa ukuba yonke inkqubo yokufaka i-press ye-pin nganye iyalawuleka kwaye ithembekile.Ungayibona imeko eboniswa kwividiyo kwakhona.I-PROMESS inikezela ngokuchaneka okuphezulu, i-100% yezisombululo zolawulo lwenkqubo yokuqinisekisa ukuba zonke iimveliso ezishiya umzi-mveliso zikhululekile kwiimveliso ezineziphene, Ukulawulwa kwenkqubo kunokunciphisa inkunkuma ye-industrial yebhodi ye-PCB ukuya kwinqanaba elithile kunye nokunciphisa iindleko zokuvelisa.

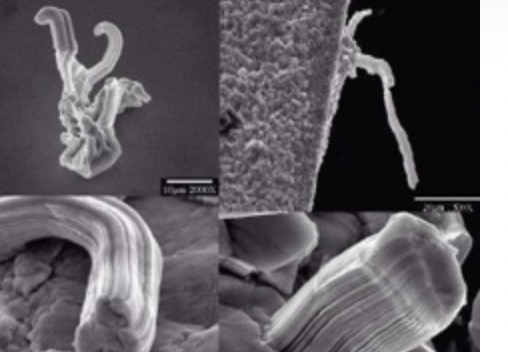

3. ISekethe emfutshane

Kumphezulu we-tin ecocekileyo, uxinzelelo luya kukhuthaza ukukhula kwe-tin Whisker, okuya kukhokelela kwisiphaluka esifutshane sesekethe kwibhodi yesekethe eprintiweyo, ngaloo ndlela ibeka engozini umsebenzi wemodyuli.Izikhokelo zoyilo lokunciphisa ukukhula kwamabhobho enkcenkce abandakanya ukunciphisa amandla okufaka kunye nokunciphisa ubukhulu be-tin surface.

Izinto eziqhelekileyo zokugquma i-PTH ziquka ubhedu, isilivere, i-tin, njl

Indlela yokusombulula ingxaki ye-tin whiskers?

Ngexesha lokucinezela, amandla oxinzelelo akayi kuba mkhulu kakhulu, okulawula inkqubo yokucinezela.Emva koxinzelelo, uvavanyo lwesampulu lunokwenziwa, kwaye amabhovu enkcenkce aya kujongwa kangangeeveki ezili-12.

4. Vula isiphaluka

Isiphumo seJet/tsalela phantsi:

Ngexesha lenkqubo yokucinezela kwi-Pin, ibhodi yesekethe eprintiweyo ingonakaliswa ngoomatshini.Ukuba i-friction inkulu kakhulu, ubuso bebhodi yesiphaluka buya kutshitshiswa, ukuxutywa kuya kwanda, kwaye ekugqibeleni i-PTH iya kugxothwa ngesigaba.Ukunciphisa uxinzelelo kunokuthintela umphumo wejethi.

Isiphumo sokwenza mhlophe/deyibalisa:

Ngexesha lokunyuswa kokushicilela, isakhiwo ngasinye sebhodi yesekethe eprintiweyo siya kucudiswa.Ukuba i-force esetyenzisiweyo inkulu kakhulu okanye i-PTH ayizinzile, ibhodi yesekethe eprintiweyo inokupheliswa.Emva kwexesha elithile, umswakama uya kungena kwiintanda zebhodi yesekethe eprintiweyo, okukhokelela ekunciphiseni ukusebenza kokuzimela

Ezi ngxaki zimbini zinokulawulwa ukuya kuthi ga kwinqanaba elithile ngexesha lokufakwa kwenkqubo yokushicilela ngokulawula amandla oxinzelelo.Emva kokuba ukufakwa kweendaba kugqityiwe, imveliso inokuhlolwa kwakhona ngovavanyo lokumelana noqhagamshelwano kunye nohlalutyo lwe-metallographic.Uvavanyo lokumelana noqhagamshelwano lunokusetyenziswa njengento yovavanyo lwesiqhelo, kwaye uhlalutyo lwe-metallographic ngokwalo luyonakalisa imveliso, ngoko ke ukuhlolwa kwesampulu rhoqo kunokwenziwa.

Iindlela zokuvavanya ukuthembeka kwemveliso eqhelekileyo

Enye yeendlela zokubona eziqhelekileyo luvavanyo lokuguga kwaye enye luvavanyo lweempawu zoqhagamshelo

Ukuguga kukulinganisa urhulumente emva kwexesha elide lokusetyenziswa ngezixhobo zovavanyo.Iindlela eziqhelekileyo zokuguga ziquka:

1. Ukugungxulwa okufudumeleyo: - 40 ℃ ~ 60 ℃, utshintsho oluqhubekayo imizuzu engama-30

2. Ubushushu obuphezulu: 125 ℃, iiyure ezingama-250

3. Ulandelelwano lwemozulu: iiyure ezili-16 ubushushu obuphezulu → iiyure ezingama-24 kushushu kwaye kufuma → iiyure ezi-2 ubushushu obuphantsi →

4. Ukungcangcazela

5. Ukutya kwegesi: iintsuku ezili-10, i-H2S, i-SO2

Uvavanyo ikakhulu kukuvavanya amandla okutyhala kunye nokusebenza kombane.

Iindlela eziqhelekileyo ziquka:

1. Sula ngaphandle amandla (amandla okubamba): > 20N (ngokweemfuno zoyilo lwemveliso)

2. Ukuchasana noQhagamshelwano: < 0.5 Ω (ngokweemfuno zoyilo lwemveliso)

Ixesha lokuposa: Nov-10-2022

Youtube

Youtube