Isidingo se-Automation-ready Solderless Interconnects

Ukudala izisombululo ze-on-board interconnect yinkalo yomngeni obalulekileyo wokuphunyezwa kweenkqubo ze-solder-free soldering.Enye indawo ephambili yabenzi bomthamo ophezulu kukugcina ukusebenza kakuhle kwemveliso.Iinkqubo ze-solder zesibini eziye zafuneka ngokwesiko ekufakeni izihlanganisi ezinkulu kunye nezinye i-interconnects ezikhethekileyo kunzima kakhulu ukuguqula kwiinkqubo ezingenalo i-lead.Oku kunzima kakhulu kwiiPCB zobhedu ezinzima ezifana noqhagamshelwano lwamandla.

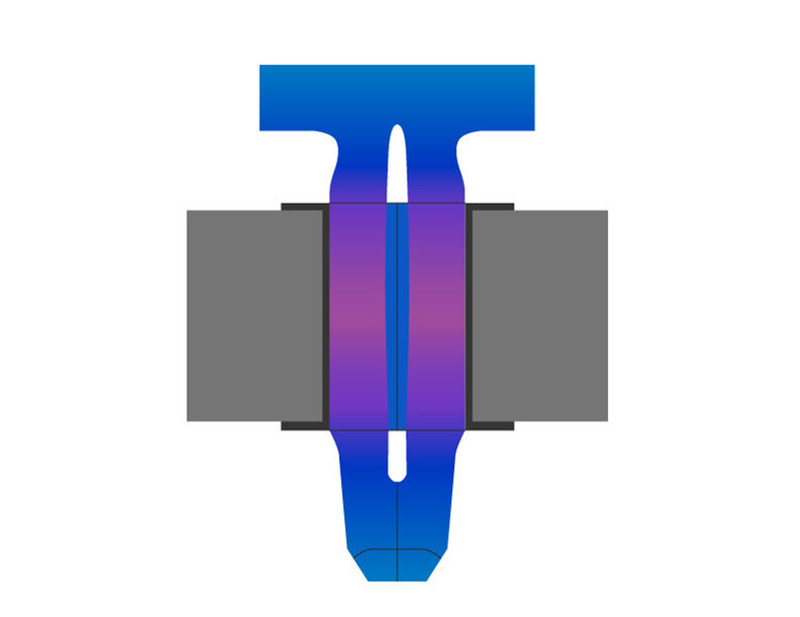

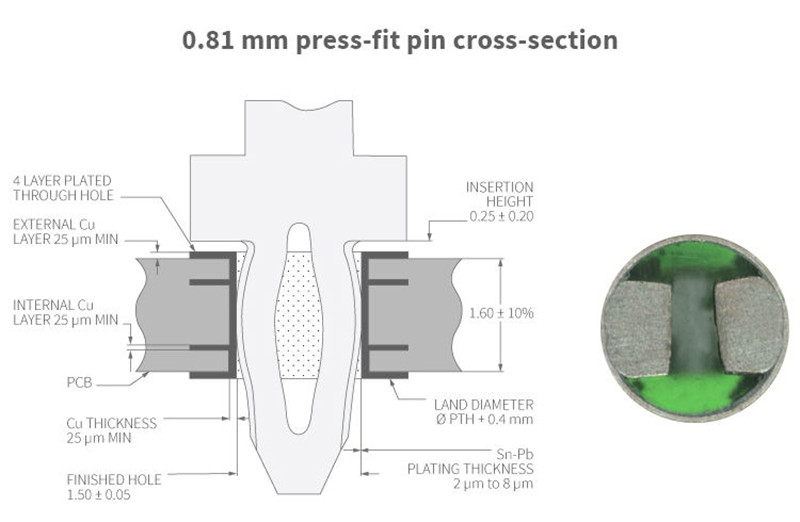

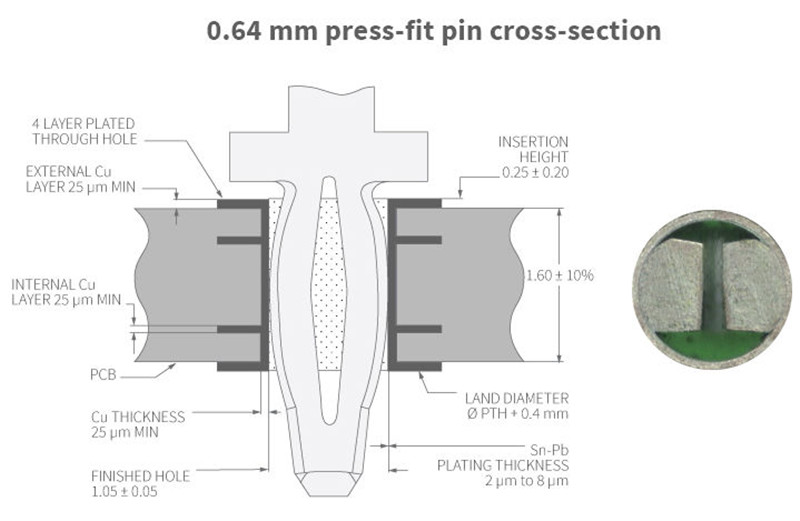

Izikhonkwane ze-Press-fit (ezithobelayo) zikhona ngaphezu kweminyaka engama-20, kunye nokusetyenziswa ngokubanzi kwiimarike ekujoliswe kuzo.Itekhnoloji ye-Press-fit (ethobelayo) ibandakanya uyilo olukhethekileyo lwecandelo lofakelo lwephini ngalinye, elibonelela nge-interface eqinile kwaye ethembekileyo ye-gas-tight kunye ne-plated-through hole kwaye ayifuni inyathelo elilandelayo le-soldering.

Icandelo lofakelo lephini likhulu kunobubanzi bomngxuma kodwa lenzelwe ukonakala ngexesha lofakelo, nto leyo eyenza i-friction-fit eyomeleleyo phakathi kwe-pin kunye ne-plated-through surface.

Uyilo lweNtuthuko lweNaliti

Ukutyhubela iminyaka, uninzi lweendlela zokuyila ezahlukeneyo ziye zasetyenziswa ukubonelela ngokufanelekileyo okufunekayo kwizikhonkwane ezithobelayo.Njengoko iteknoloji ye-press-fit (ethobelayo) ihambela kwizicelo ezitsha ezifana neeBhokisi ze-Smart Junction, kwishishini leemoto, kubalulekile ukuba amandla phakathi kwepini kunye ne-plated-through surface ahlale ngokwaneleyo ukumelana nokusingqongileyo kunye nemiba yomatshini efana nokushisa, ukufuma, ukungcangcazela, ukothuka kunye nezinye iimeko ezimagingxigingxi ezizezendalo kwimekobume yemoto.

Indlela "ye-eye-the-needle" ibonakaliswe ukuba ibonelele ngeteknoloji ethembekileyo yokuphucula amandla okuqala kunye nokugcina amandla.Uyilo olufana nolwasentwasahlobo olusetyenziswe kwi-eye-of-the-needle configurations lubonelela ngamandla oqhagamshelwano olusondeleyo lwexesha elide ngokuchasene nombhobho womngxuma.

Ubushushu bokusebenza kuzo zonke izikhonkwane yi-40 ukuya kwi-125 C, kwaye ziyakwazi ukumelana ne-125 C ngeeyure eziyi-1,008.Izikhonkwane ze-engile ekunene (umqolo omnye kunye nophindwe kabini) zikwakhona ngokujoyina ii-PCBs ze-perpendicular.Zonke iimveliso zibonelelwa nge-RoHS ekhokelela kwiplating yasimahla.

Izihlanganisi zibunjwe ngeplastiki ehlala ixesha elide kunye noluhlu olubanzi lwezikhonkwane.Zisenokuba nezikhonkwane ezimbalwa ezinokuba ngama-256.”: Iphephancwadi i-Assembly Magazine litsho kwinqaku elithetha ngeziqhagamshelo zePress-fit neengenelo zazo.

Umthamo wangoku wokuthwala

Iitheminali ze-Press-fit (ezithobelayo) zinomthamo ogqwesileyo wangoku kwaye zinokuba luncedo ngakumbi kunxibelelwano lwamandla kwiibhodi zobhedu ezinzima, ezinokuba nzima ukuzithengisa kwaye ngenxa yoko kunzima kakhulu ukutshintshela kwiindawo ezingenalo ilothe.Endaweni yokuba kulungiswe okanye kuhlengahlengiswe iiparamitha zenkqubo yokuqukumbela ukuze kuhlangatyezwane nemingeni ekhethekileyo yokuthengisa iiPCB zobhedu olunzima, abavelisi banokuseka iifestile zolawulo lwenkqubo ebanzi ngokubanzi kwaye baphelise iimfuno ezikhethekileyo zokuthengisela ngokusebenzisa unxibelelwano oluhambelanayo lwezicelo zangoku.

Uvavanyelwe ukuthembeka, ukugcinwa kwamandla kunye nokuchasana nokusingqongileyo

Uhlobo lwe-eye-of-the-needle I-teknoloji ye-Press-fit (ethobelayo) iye yavavanywa ngokubanzi ukuqinisekisa ukuthotyelwa kwenani leemfuno eziphambili zeshishini, kuquka i-SAE / USCAR-2, i-Rev4, i-EIA Publication 364 kunye ne-IEC 60352-5 iinkcukacha.Inkqubo yokuvavanya isebenzise uvavanyo olucwangcisiweyo lwezinto ezisingqongileyo, oomatshini kunye nokuthembeka phantsi kweemeko ezilawulwayo.

Uvavanyo lwenziwa kuluhlu lweentlobo ezahlukeneyo zokudityaniswa kwe-Press-fit (ethobelayo) kunye neentlobo ze-PCB (kubandakanywa nokucwenga kobhedu, ukucwenga kwegolide kunye nokugqiba kwe-HASL).Zonke iisampulu zovavanyo zenziwe zadityaniswa kusetyenziswa ubuchule obuqhelekileyo bemveliso kunye neendlela zomgangatho.

Uvavanyo oluthile lubandakanya ukungcangcazela, ukothuka kwe-thermal kunye nobomi bobushushu, ukothuka komatshini, amandla okufaka, amandla okugcina, ukufuma, ukukhwela ibhayisekile yangoku kunye nokuchasana nokunxibelelana.Lonke uyilo loqhagamshelo lugqithiselwe ngokuqhubekayo ngaphandle komonakalo kunye/okanye ukuthotyelwa kweeparamitha ezichaziweyo.

IiNkcazelo zePin ezithobelayo, ulungelelwaniso, uKhetho

I-Press-fit (ethobelayo) uthungelwano ngoku lufumaneka kolu lungelelwaniso lulandelayo:

Iitheminali ezikhethekileyo (iincakuba, iithebhu, njl.njl.)

Izikhonkwane eziqhubekayo

Cinezela-faka iiheader kwiireli eziqhubekayo okanye ubude bokusika kwangaphambili (enye-nge okanye ezimbini-by)

Isikwere okanye ukungqukuva (umgangatho weshishini okanye idiameter yesiko & nobude bephini)

Ixesha lokuposa: Jun-22-2022

Youtube

Youtube